What makes a good removable tape? It obviously should hold as much weight as possible and remove from the surface without leaving a residue that then needs to be cleaned up.

Many believe that the adhesive is the most important component for a good removable tape. Just figure out how much shear strength you want and match up an adhesive that will give you the desired shear value. This is often how adhesive tapes are developed, figure out the strength you want in an adhesive.

For a removable tape, this is the wrong approach.

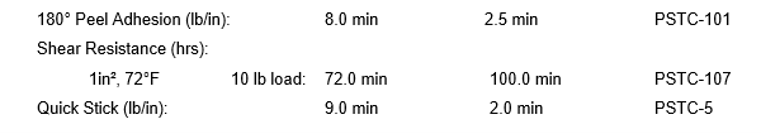

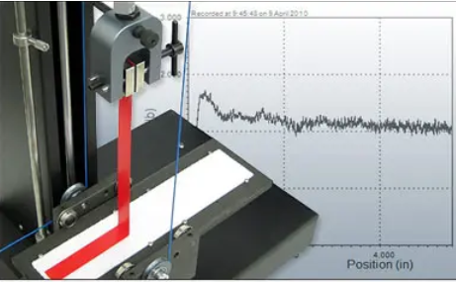

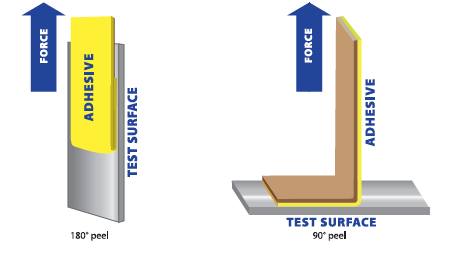

Adhesive tapes have data sheets that measure the strength of an adhesive measured with a force, resulting in weight force per inch. Say a removable tape measures 40 oz per inch force to remove the tape peel adhesion and it works great for the application. You find another tape that also has 40 oz per inch force to remove the tape peel adhesion, but the result is very different from the other tape with the same strength. What gives?

When tape shear and peel adhesion is measured, it is on a stainless-steel plate. The reason for this is so all tape is measured on the same substrate and start on the same benchmark. If one company measures tape strength on stainless steel and the other on plastic, their resulting values could not be compared with one another and give you a comparable value, so the industry uses stainless steel when you see those values on data sheets. However, it does not give you real-world values for specific applications.

So when evaluating a removable tape, you could pretty much ignore the data sheet values.

While adhesion value is important in a removable tape (you don’t want a very high peel value), the key is the tape construction and knowing what your surface is like.

If the surface does not delaminate, like metals and plastics, you’ll have more tape options. If surface does delaminate, like drywall, stucco, certain painted surfaces, finding the right removable adhesive tape will be more challenging.

What removable tape will be strong enough and broad enough to work on as many surfaces as possible? The construction of the adhesive will make the biggest difference.

We will focus on removable foam tapes. Foam is good to use because in works best on broader surfaces, particularly uneven surfaces like that of many interiors that feature textured walls.

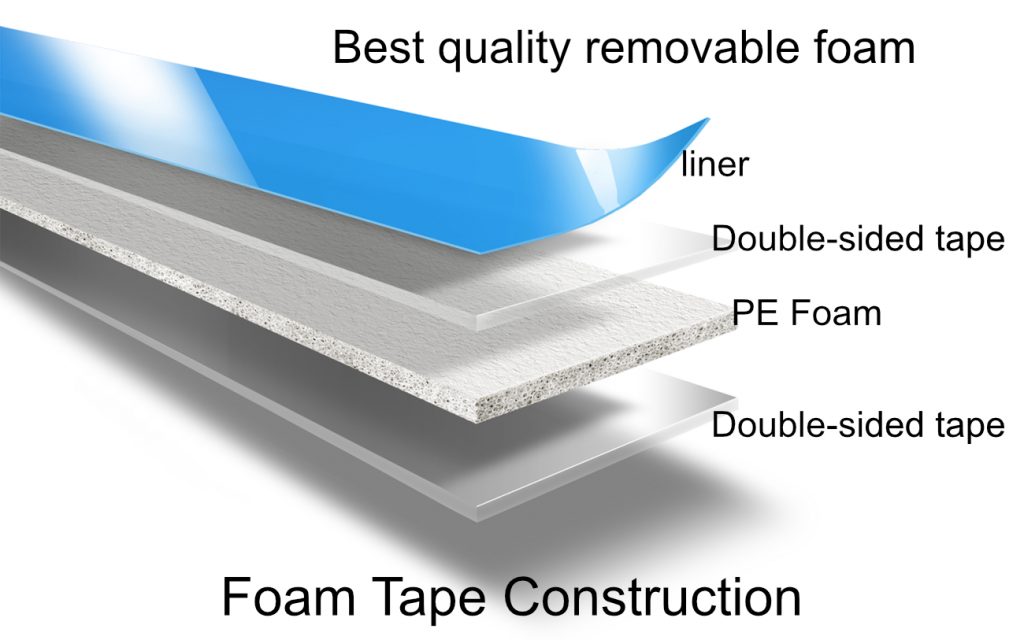

There are two ways to apply adhesive on a foam (most common a cross-linked polyethylene foam).

- Apply adhesive directly on the foam

- Apply another double-sided tape layer on top of the foam

The most common removable tape construction is to apply adhesive directly on top of the foam. The advantage is the tape is cheaper priced. It will also not hold much weight. Over time the adhesive tends to sink into the pores of the foam, weakening the bond even more.

With the second option, the tape bond is stronger, but because there is an extra layer, it means slower processing and extra material used so the price is more expensive. Some manufactures use a double-sided pet film tape or tissue layer. Remo One (one sided removable other side permanent) and REMO Two (both sides removable) are the gold standard for a polyethylene removable foam tape. They work on a multitude of surfaces, even paper, and hold heavier objects relatively well. The only draw back is they are intended for indoor use. See Ghost and Gecko tapes for an outdoor removable.