You just want a tape that is sticky on both sides for your project and works with your budget, but then you realize there are choices to make.

The first question a tape professional will ask is what’s the application. The question serves to eliminate options and to narrow down viable tapes. The application of a specific project should inform the type of tape to focus on. Identify:

- The type of surfaces that will be bonded with the tape

- Smooth or rough surface

- If rough surface, this might indicate need for a flexible tape or thick adhesive (to fill in gaps in a rough texture)

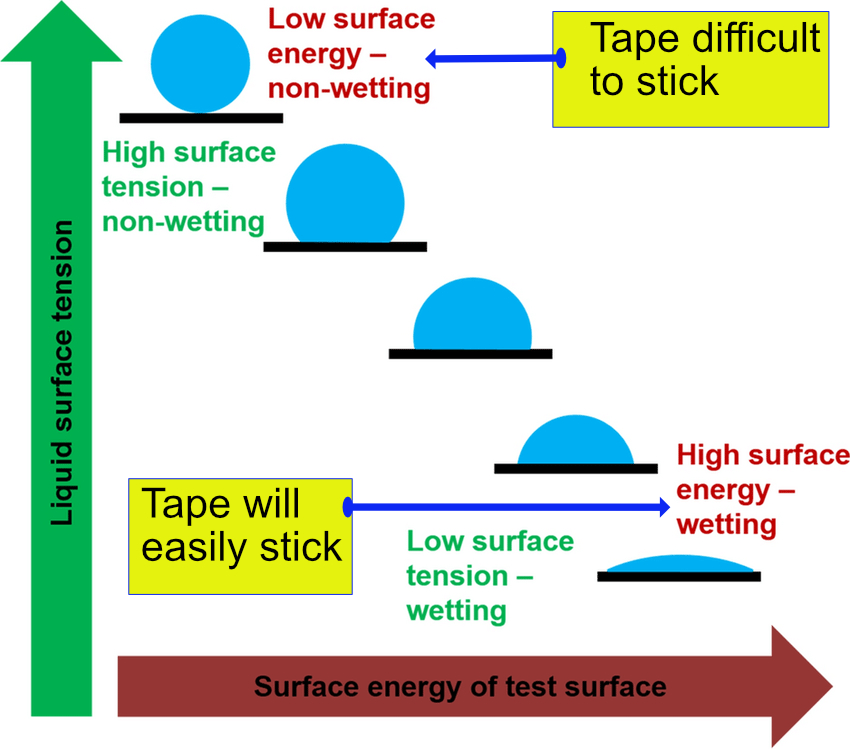

- Is the surface low energy (hard to stick to) or high surface energy (easy to stick to)

- Smooth or rough surface

If low surface energy, like polyethylene plastic, then need an adhesive that will bond (flow) onto hard to stick to surfaces.

- Permanent or temporary hold? This question may not be as straight forward. You may have a case where you want to remove the adhesive cleanly from the surface but the adhesive tape designed for removability is too weak. It could be that you have a low energy surface and actually need a tape designed for permanent bonding, since it will remove from certain low energy surfaces. So know if you have an easy or hard to stick to surface. If hard to stick surface, try a “permanent bond tape” that has a relatively weaker adhesive bond.

- Outdoors or indoors, and any exposure to very hot or cold temperatures?

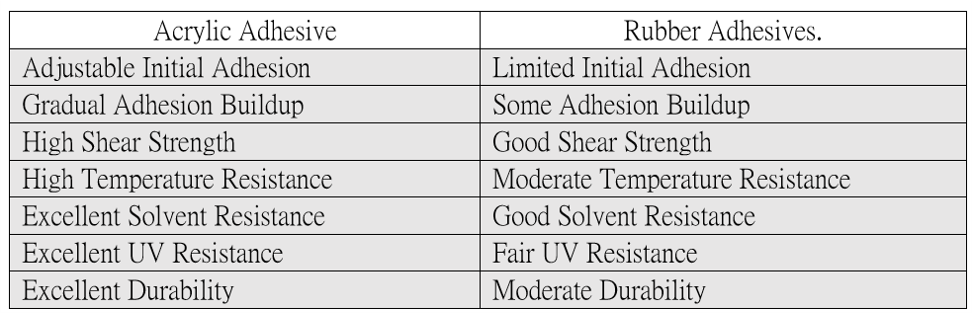

- If indoors, you could use rubber or acrylic adhesive tape. Rubber adhesive tends to wet-out better and therefore you get a quicker bond to the surface.

- If outdoors, the general rule of thumb is to use an acrylic adhesive. The reason for this is that it is assumed that it will be exposed to higher heat and cold, possible exposure to moisture and direct uv sun. Today, rubber and acrylic adhesives are not too far apart on cost (the thickness of the adhesive is usually the driver of cost of a roll of tape).

- What forces will act on the tape over time?

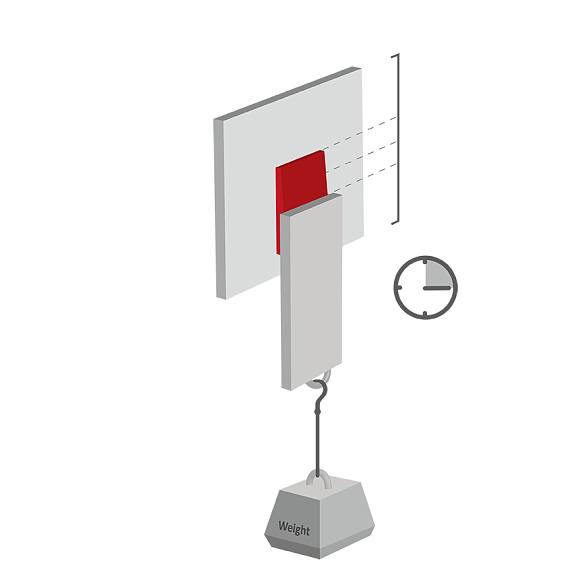

- A common force is vertical pressure (static shear force–pictured example below), for example, a piece of art hanging from the wall. If you have an object hanging from the ceiling then you need a tape with good tensile (elongation) hold.

- If a constant force is being applied on the tape over time, choose a foam tape (particularly if rough textured surface) or a film tape (for smooth surface and you want a thinner tape).

- What is your tape budget?

- If you are very price conscious, choose a tape with the least amount of adhesive and thickness as possible while still delivering on your performance needs.

- As stated earlier, the thickness of the tape is usually the biggest component of the cost to make a roll of tape. And it is not that you are actually using more adhesive, but the thickness of the tape determines how fast a manufacture could make that roll of tape. The thicker the layer of adhesive (usually measured in mils), the slower machinery needs to run. It is slower to coat on thicker adhesive but the adhesive also needs to dry in an oven. The thicker the adhesive the longer it needs to stay in the oven (tape manufactures have ovens that are hundreds and even thousands of feet long).

1 mils considered very thin adhesive tape

3-4 mils medium amount of adhesive thickness

6-8 mils of adhesive is very thick.

for visual comparison, a typical business card is about 10 mils thick.

Contact us for a tape recommendation for your project. Information is always free!