We will focus on double-sided foam and film tapes cut pieces.

If you are applying thousands of pieces of tapes cut from continuous rolls, consider the costs savings of pre-cut tapes pieces.

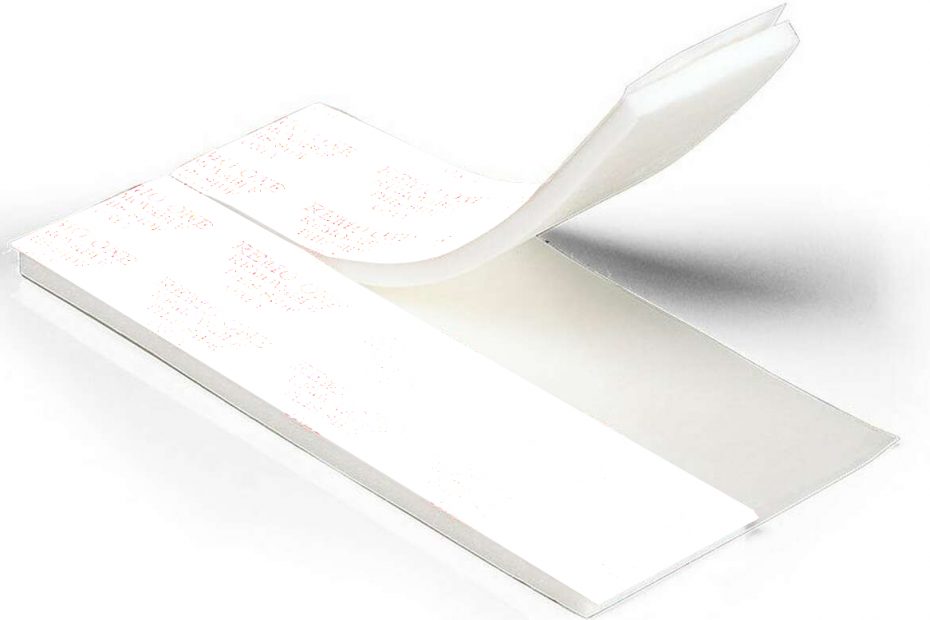

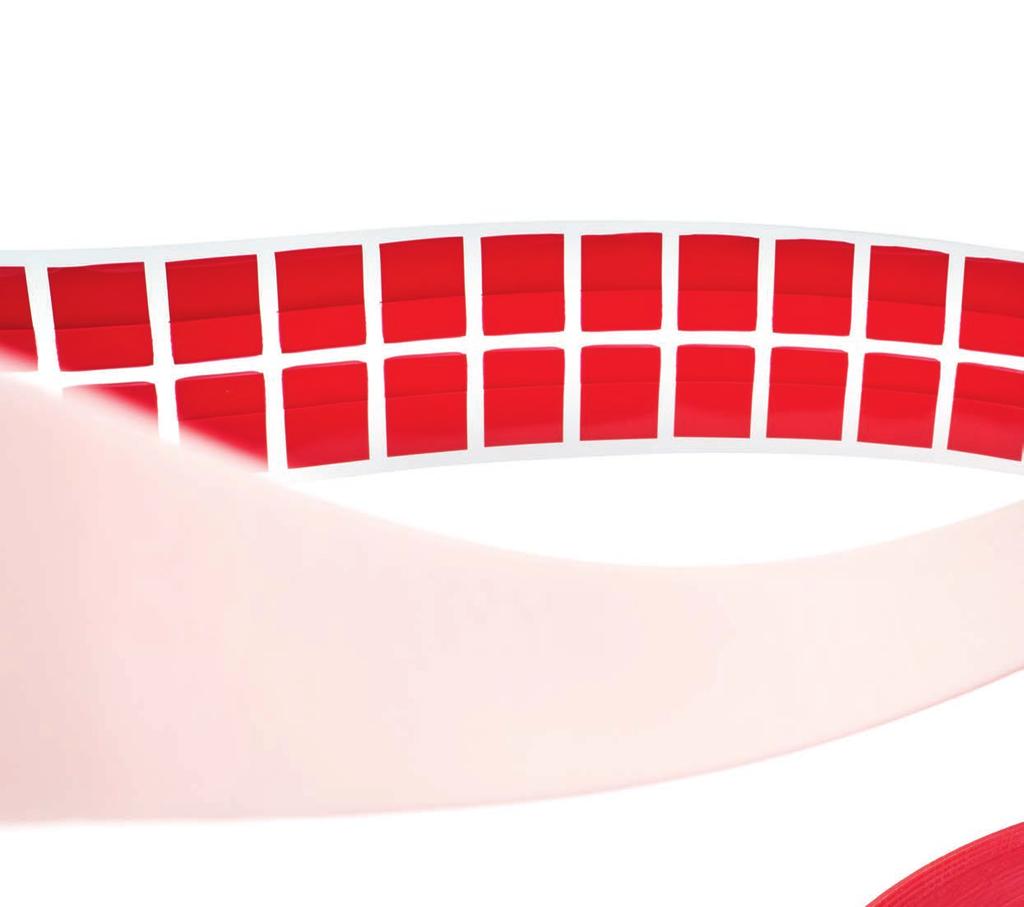

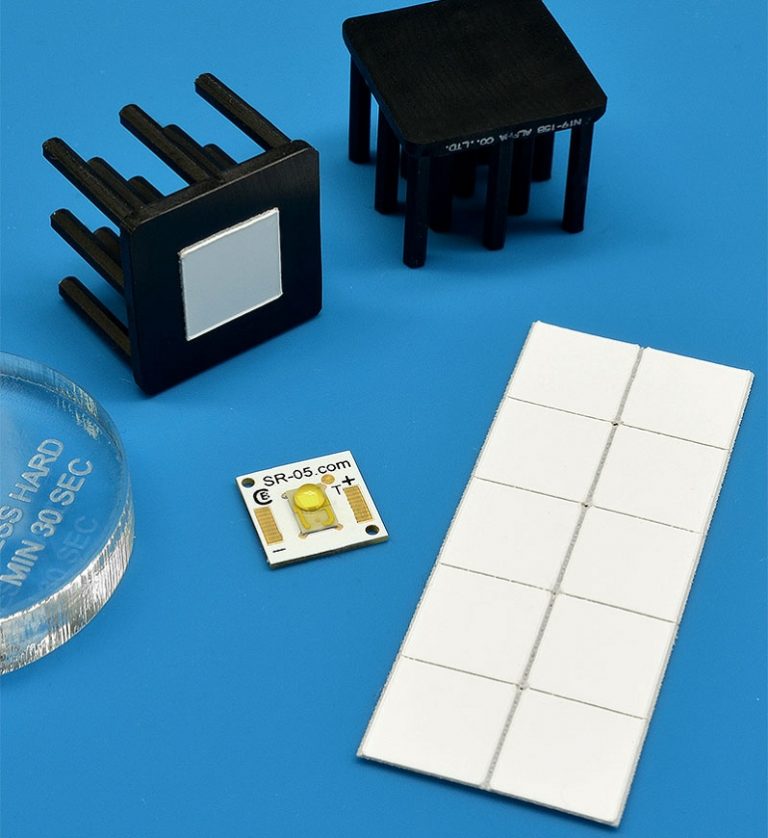

Pre-cut tape pieces could be as small as ½” x ½” on a roll or pieces on a pad. Then it’s just a matter of peeling and sticking the tape on your work.

While the price per square foot is more for pre-cut tape pieces as compared to continues roll of tape, your overall cost could be considerably less expensive.

Cost saving on labor hours.

A company calculated their labor used for processing POP displays where tape was used. It took an average worker 80 minutes to apply 1,000 pieces of tape. He same average worker was able to apply 1,000 pieces of tape in 25 minutes. The 55 minute difference multiplied by a dozen workers meant that they lost 660 minutes per every 1,000 cut pieces. Costly in terms of hourly output and getting the job done on schedule.

Also consider that when workers need to cut thousands of pieces by hand, accident will happen.

In order to assure efficient processing of cut pieces of tape, be certain that the liner is easily removed. Nothing is more frustrating to workers than having difficulty removing the top protective line from thousands of pieces of tape. Your tape converter should supple pre-cut tape pieces on a roll or pad with a finger tab, or an extended liner, where it makes it easy to grab and peel away the liner.

Pre-cut tape rolls usually have 1,500 to 2,000 pieces per roll. But if you just need a few dozen or even a hundred pieces at a time, then you might want to cut them yourself using an automatic tape cutting machine. They are relatively low cost and a time saver.

The video below shows a simple desktop unit that could cut double-sided tapes, even High Bond (.5mm thick)