Silicone LED strips usually mean silicone extrusion, silicone encapsulation, or silicone conformal coating instead of epoxy or PU.

Key Advantages of Silicone LED Strips

✅ Superior Environmental Resistance

- Excellent UV resistance (won’t yellow like epoxy)

- Stable in outdoor, sun-exposed installations

- Wide temperature range (typically -40°C to +150°C)

➡️ Ideal for: outdoor signage, architectural façades, marine, automotive

✅ Long-Term Flexibility

- Silicone stays soft and elastic over time

- Does not crack or harden with age

- Maintains bend radius even in cold weather

➡️ Critical for: curved channels, vibration-prone installs

✅ Better Heat Tolerance

- Silicone withstands higher operating temperatures

- Less risk of delamination or cracking near LEDs

- Improves lumen maintenance over time

➡️ Especially valuable for high-density or high-output strips

✅ Excellent Waterproofing (IP67 / IP68)

- Silicone seals remain stable over time

- Better resistance to saltwater and chemicals than epoxy

➡️ Used in: pools, fountains, boats, industrial washdown areas

✅ Optical Quality

- Silicone diffusers provide:

- Even light distribution

- No yellowing haze

- Stable color rendering over time

⚠️ Trade-Offs of Silicone LED Strips

Consideration | Notes |

Cost | Higher than epoxy or PU |

Adhesion | Silicone is hard to bond with standard tapes |

Dirt attraction | Slightly tacky surface attracts dust |

Cutting & sealing | Requires proper end caps or RTV silicone |

Adhesion & Mounting (Important!)

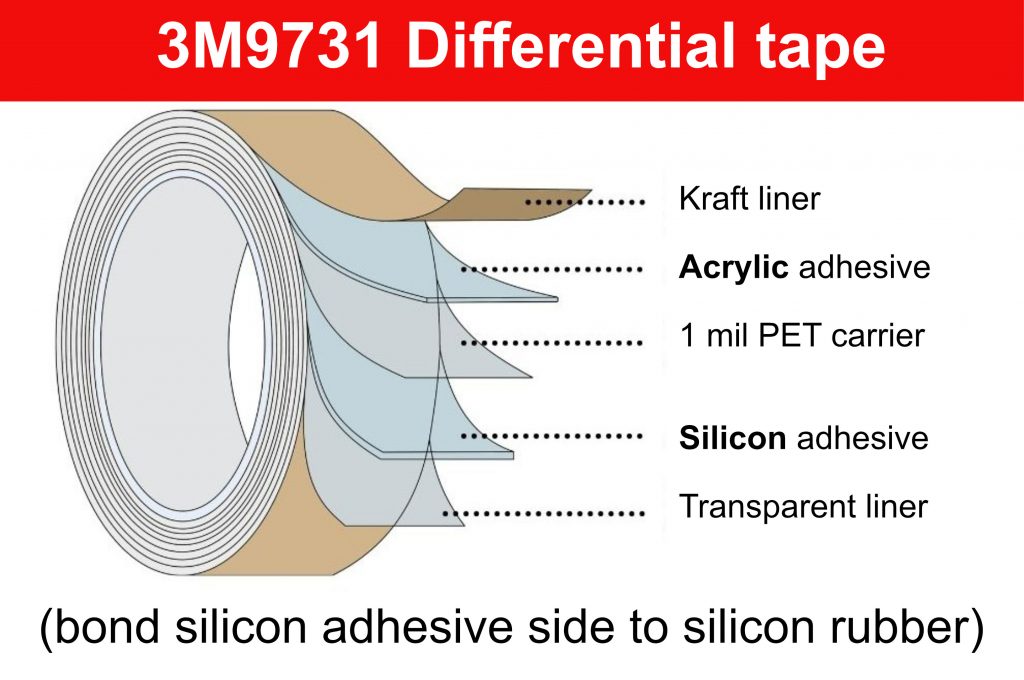

Since silicone is notoriously low surface energy (LSE), you will need an adhesive that will work not only with LSE materials but silicone specifically. While there are tapes designed for LSE surfaces, the usually recommended tapes will disappoint since silicone is not only extremely low surface energy (~20–24 dynes/cm) there are other surface properties that make bonding to silicone rubber foam very challenging.

- Mechanical mounting (aluminum channel) is best

- RTV silicone

- If tape is needed:

- Silicone PSA like 3M 9731

- Best when shear forces or lighter weight materials.

- Silicone PSA like 3M 9731

When Silicone LED Strips Make the Most Sense

Choose silicone-based LED strips if:

- Outdoor or UV exposure is involved

- Long service life matters (commercial installs)

- Tight bends or vibration exist

- Moisture, chemicals, or temperature extremes are present

If it’s indoor, dry, budget-driven → standard coated or bare PCB is often fine.

- Extremely low surface energy

Silicone’s surface energy is ~20–24 dynes/cm (very low).

Most adhesives want ≥38 dynes/cm to wet out properly.

- Chemically inert surface

The Si–O backbone is very stable and non-reactive.

There are few functional groups for adhesives to chemically grab onto.

- Migration of silicone oils

Unreacted siloxanes and low-molecular-weight oils can slowly migrate to the surface.

- High flexibility + elastic recovery

Silicone stretches a lot and snaps back aggressively.

- Thermal stability works against you

Silicone stays flexible from roughly –60°C to +200°C.

- Poor compatibility with common adhesives

- Acrylic PSAs

- Rubber-based adhesives

- Hot melts

They simply weren’t designed for silicone’s chemistry. 3M 9731 has been successfully used with silicone LED strips.