I find it surprising that people choose a very high bond (VHB) tape based on its color. In the case of clear or transparent VHB, the color, or lack of color, just happens to also be a fit for the application, as the clear VHB is best suited for glass and and many clear plastics. On the other hand, grey and black VHB may not be the best option solely based on color. Here we will see which VHB is best suited for a particular project.

Core VHB Families & What Makes Each One Unique

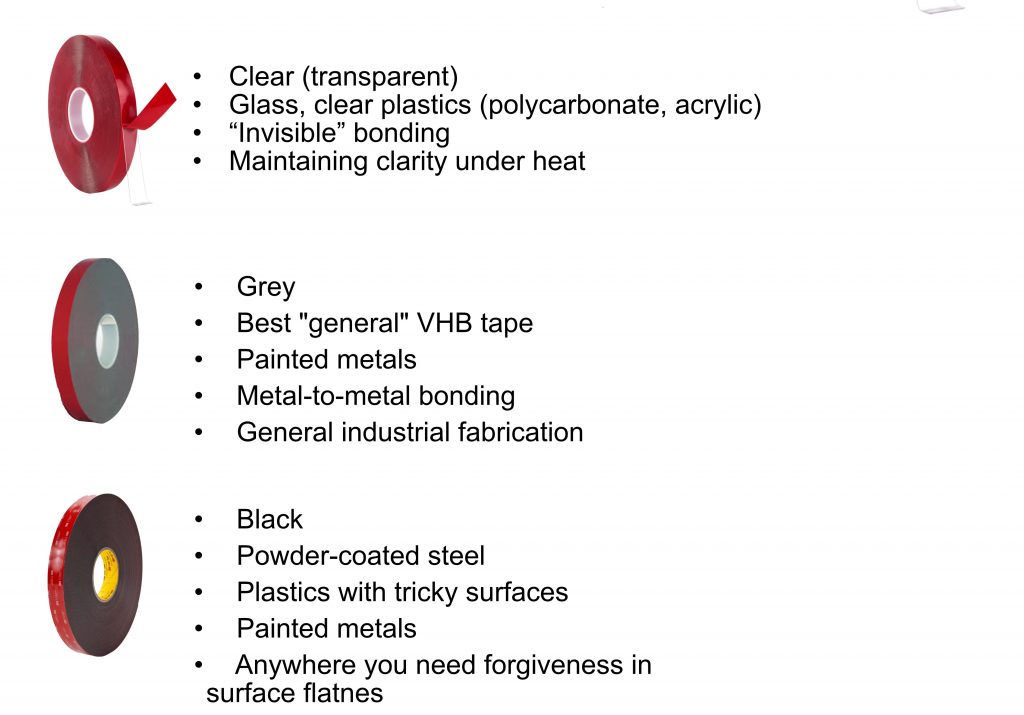

1) The Clear, Hard Acrylics (3M 4905, 4910 and equivalent )

Colors: transparent

Foam type: firm, high-modulus acrylic foam

Adhesive type: hard, high-shear acrylic

Formulation Characteristics

- Uses a higher-hardness acrylic polymer (less rubbery).

- Closed-cell foam is denser and stiffer; fewer additives.

- Adhesive layer is tuned for high shear strength but lower initial tack.

- Clear formulation limits fillers and pigment-containing components.

Best at:

- Glass, clear plastics (polycarbonate, acrylic)

- “Invisible” bonding

- Maintaining clarity under heat

Weak spots:

- Not great with low-surface-energy plastics (PE, PP, powder coat)

- Needs more pressure and time to wet out because it’s stiffer

Think of the 4910 family as “elegant but picky.”

2) The Workhorse Gray Series (general-purpose)

**

Colors: gray

Foam type: medium-firm acrylic foam

Adhesive type: general-purpose acrylic adhesive

Formulation Characteristics

- Uses a balanced acrylic blend — not too soft or too hard.

- The gray pigment allows use of different monomers/additives.

- Has moderate “cold flow” (slow creep to fill gaps).

- Better adhesion to metals and many paints due to aggressive surface wet-out.

Best at:

- Painted metals

- Metal-to-metal bonding

- General industrial fabrication

Weak spots:

- Not ideal for textured plastics or LSE plastics

- Less tolerant of uneven surfaces than the softer families

The 4941 family is the “machine shop default.”

**3) Soft, Super-Wet-Out Acrylics (King of Difficult Surfaces). 3M 5952 and equivalent

**

Colors: black

Foam type: very soft, conformable acrylic foam

Adhesive type: modified LSE-capable acrylic adhesive

Formulation Characteristics

- Much softer acrylic foam core — lower modulus, more flexible.

- Adhesive is ultra-tacky, loaded with components that improve wet-out.

- Conforms to texture, powder coat orange-peel, irregular surfaces.

- Stronger peel strength than the gray or clear families.

Best at:

- Powder-coated steel

- Plastics with tricky surfaces

- Painted metals

- Anywhere you need forgiveness in surface flatness

Weak spots:

- Not ideal for glass or clear applications

- Slightly lower long-term shear at high temps (tradeoff for softness)

This is the “everything sticks to it” tape.

To Summarize:

See our 3M and comparable VHB tapes in our shop page.

Family | Foam Hardness | Adhesive Softness | Wet-Out Ability | Temp Resistance | Target Surfaces |

4910 (clear) | Hard | Hard | Medium-Low | High | Glass, acrylic |

4941 (gray) | Medium | Medium | Medium | High | Metals, general |

5952 (black) | Soft | Soft/Tacky | Very High | Medium | Powder coat, plastics |

4991 (LSE) | Medium-Soft | Soft/Tacky | Extremely High | Medium | PE/PP/LSE plastics |

4622/4611 | Very Hard | Hard | Medium | Very High | Metals, bake cycles |