From San Diego, California 2022

Low surface energy parts (materials that are hard to stick tape to) present a problem when you are trying to find a double-sided tape to bond to the material. Silicone is a widely used material that comes in film and foam forms, and since it has very low surface energy properties, very few double-sided tape options exist.

The best option for silicone material bonding with double sided tape is to use a silicone adhesive.

Automotive, Medical, and electronic are some of the industries that use silicone products.

Here is a list of other commonly used materials that have low surface energy where a silicone tape may be considered to create a tight bond.

| Polyvinyl (PVF) Poly(chlorotrifluoroethylene) Polyethylene – PE Polypropylene – PP Poly(methylmethacrylate) – PMMA Polystyrene (styrene) – PS Polyamide – PA, Nylon-6,6 Polyvinyl chloride – PVC Poly(vinylidene chloride) Poly(ethylene terephthalate) Epoxy – typical rubber toughened Epoxy – typical amine-cured Phenol-resorcinol resin Urea-formaldehyde resin Styrene-butadiene rubber Acrylonitrile-butadiene rubber Carbon fibre reinforced plastic (CFRP) abraded | 19.1 30.3 33.5 32.4 33 (*) 40.2 40.6 41.4 41.5 45.0 45.1 45.5 46.2 52 (*) 61 (*) 29.1 36.0 |

If cost or thicker tape is desirable, consider testing a very tacky rubber based adhesive foam tape.

A good option if silicone is the only viable alternative, and to to keep costs down while maintaining performance needs, a differential adhesive that features silicone adhesive on one side and a high performance acrylic on the other side. The silicone side would bond to the silicone, or low surface energy side, while the acrylic side would be applied to the non-silicone substrate. The silicone and acrylic will perform effectively across a range of applications, including high temperature performance, good solvent resistance, very good holding power and excellent UV resistance.

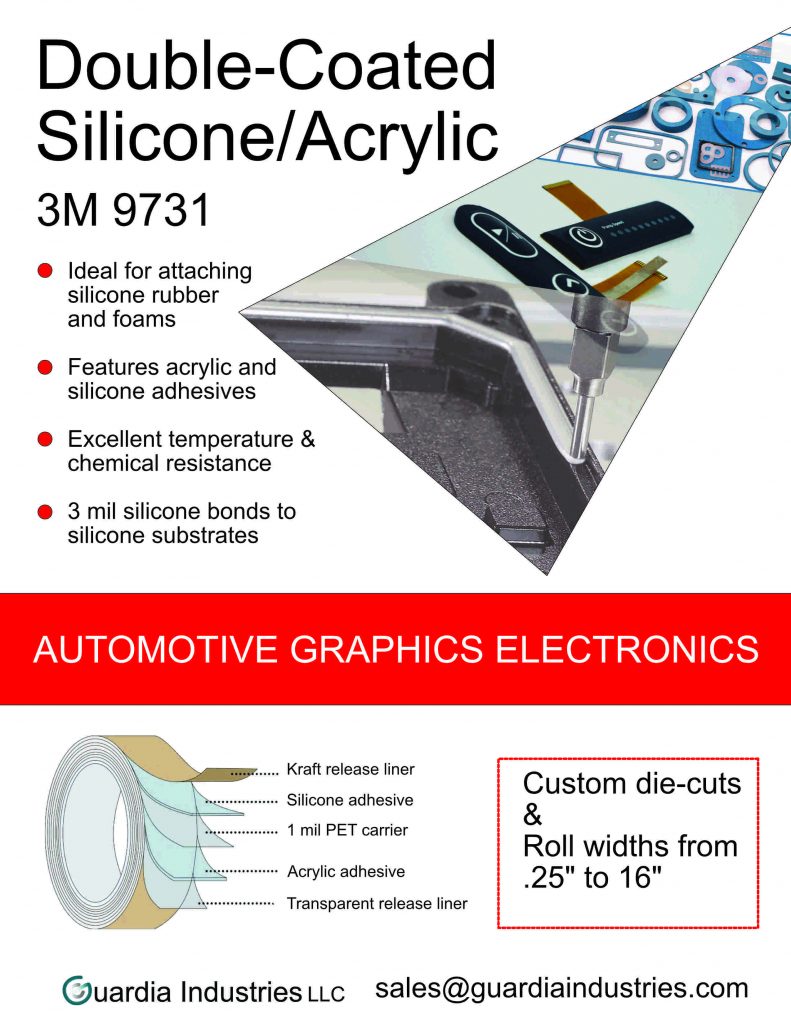

3M™ Double Coated Tape 9731

Details

Ideal for attaching silicone rubber elastomers and foam

Features acrylic and silicone adhesives for specialized applications such as silicone gasketing

3M™ Adhesive 350 on the face side provides exceptional temperature and chemical resistance

3 mil silicone adhesive on liner side bonds well to silicone substrates

Double linered – Adhesive 350 on 58# 4.2 mil PCK liner and silicone adhesive on 3 mil PET liner

3M™ Double Coated Tape 9731 was developed with a high-performance acrylic adhesive on the face side and a silicone adhesive on the liner side of a 1 mil clear PET carrier. It is excellent for demanding applications where silicone materials must be bonded to a range of substrates.

Recommended Applications

- Gasketing

- Filters

- Silicone foams and rubber

For gasketing applications, silicone tape can be applied to gasketing material, which is then die-cut to provide parts. Silicon and acrylic provide instant adhesion to keep processes moving forward. Differential tape is ideal for attaching gaskets, and also for replacing gaskets or bonding and sealing simultaneously. Examples include air and liquid filters, fluid handling equipment and heat exchangers. resist fluids and provide high adhesion to foams and various silicone surfaces.

Also used in the manufacture of keypads.

Other advantages:

Consistent performance over wide temperature range [e.g. Polyimide Tapes]

Excellent aging and UV resistance [LED and outdoor applications]

High Temperature resistance [e.g. 400 F – 600F]

Good resistance to polar solvents

Bonds very well to silicone substrates such as release liners, silicone sponge and closed cell rubber,

Low initial tack allowing repositioning during application.