Double-sided adhesive tapes are extremely reliable when they’re used correctly, but most failures trace back to a handful of predictable causes. Below is a **practical, real-world breakdown of why tapes fail, how the failure occurs, and examples you’ll recognize from sign shops, electronics assembly, and industrial fabrication.

- Surface (substrate) and tape mis-matched (Most Common)

Why it fails

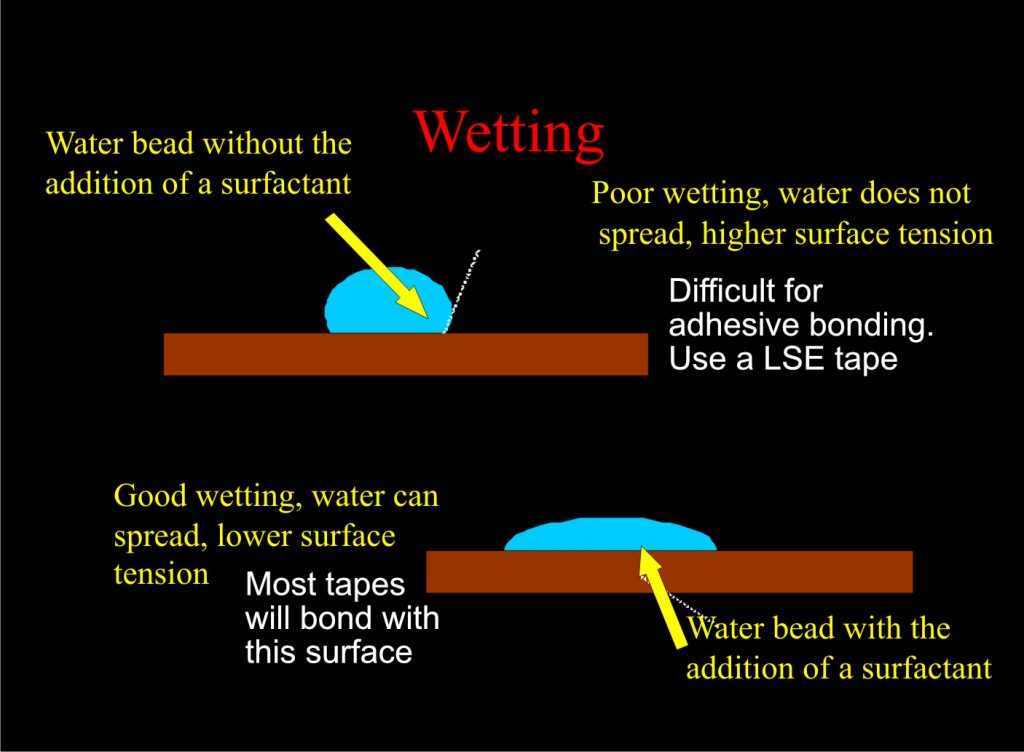

Pressure-sensitive adhesives (PSAs) bond by wetting out the surface. Some surfaces are more amenable to spreading out adhesive on its surface (meaning creating more and tighter contact with its surface). Oils, dust, silicone, or even light oxidation block intimate contact also prevent optimal wet-out. So knowing how well your material will reject (low surface tension) or promote wetting out (high surface tension), will be the first step in guiding you to the most appropriate adhesive tape for your application.

How the failure happens

The adhesive never fully contacts the substrate → reduced surface area → weak bond → peel or shear failure.

Common examples

- Nameplates falling off powder-coated panels

- Tape lifting from aluminum extrusion weeks after install

- Foam tape sticking initially, then releasing cleanly

Typical root causes

- Low surface tension substrates

- No solvent wipe (IPA recommended)

- Touching adhesive with bare hands

- Silicone mold-release on plastics

- Oxidized metals (especially aluminum and steel)

Failure signature: Adhesive stays on one side only (adhesive failure).

- Incorrect Adhesive Chemistry for the Substrate

Why it fails

Different adhesives are designed for different surface energies.

Substrate | Risk |

Low-energy plastics (PP, PE, PTFE) | Acrylic tapes struggle |

Painted surfaces | Plasticizers migrate |

Rubber / vinyl | Chemical incompatibility |

How the failure happens

Adhesive can’t wet the surface → poor initial tack → long-term creep or peel.

Examples

- Acrylic tape failing on polypropylene enclosures

- Vinyl graphics lifting at the edges

- Rubber gaskets slowly sliding out of position

Better choice examples:

- Use 3M 300LSE for low-surface-energy plastics

- Use rubber adhesive tapes for EPDM or PVC

- Use primer (3M 94) when required

- Insufficient Pressure During Application

Why it fails

PSAs are pressure-activated, not just “stick and go.”

How the failure happens

No pressure = incomplete wet-out = micro air gaps = reduced bond strength.

Examples

- Hand-applied tape vs roller-applied tape

- Large panels bonded without a J-roller

- VHB pressed lightly instead of firmly

Rule of thumb:

- 15–20 psi application pressure

- Roller > hand pressure

- Bond strength increases over 24–72 hours

Failure signature: Tape peels easily but looks intact.

- Environmental Stress (Temperature, UV, Moisture)

Be aware that adhesive tapes should be applied at room temperature for best results (once applied and tape cured, it can be exposed to their rated operating temperature). Ask your supplier for the tape’s application and operating temperatures

Temperature extremes

- Cold: adhesive stiffens → poor wet-out

- Heat: adhesive softens → creep or slip

UV exposure

- Degrades backing and adhesive over time

- Especially problematic for indoor-only tapes used outdoors

Moisture

- Wicks into edges

- Breaks bond on porous substrates

Examples

- Outdoor signs falling after summer heat

- Cold-applied tape failing in winter installs

- Bathroom or kitchen fixtures releasing

Mitigation:

- Apply above minimum temp (often >50°F / 10°C)

- Use outdoor-rated acrylics

- Seal edges where moisture intrusion is possible

- Wrong Load Type (Peel vs Shear)

Why it fails

Tape is strongest in shear, weakest in peel.

How the failure happens

Design loads pull tape at an angle or edge instead of parallel to the surface.

Examples

- Vertical signs hanging from top edge only

- Cable mounts pulling outward

- Hinged panels flexing the bond line

Design mistake:

- Tape used as a hinge or cantilever support

Better design:

- Maximize bonded area

- Load in shear

- Use mechanical fasteners to resist peel forces

- Creep Under Continuous Load

Why it fails

PSAs are viscoelastic—under constant stress, they slowly deform.

How the failure happens

Adhesive flows → bond shifts → eventual release.

Examples

- Heavy acrylic letters slowly sliding down walls

- Nameplates drifting out of alignment

- Foam tape compressing and relaxing

Warning sign: Gradual movement, not sudden failure.

Solutions:

- Increase tape thickness or width

- Switch to VHB with higher shear rating

- Combine tape with mechanical stops

- Chemical Attack or Plasticizer Migration

Why it fails

Some plastics and paints release chemicals over time that soften or break down adhesives.

How the failure happens

Adhesive loses cohesion → becomes gummy or releases cleanly.

Examples

- Tape failing on flexible vinyl banners

- Soft-touch coatings causing bond loss

- Painted surfaces with uncured solvents

Failure signature: Adhesive becomes gooey or oily.

- Aging, Shelf Life, and Storage Issues

Why it fails

Adhesives degrade when stored improperly.

How the failure happens

- Oxidation

- Loss of tack

- Backing embrittlement

Examples

- Old tape rolls used years later

- Tape stored in hot warehouses

- Edge-curling or brittle liners

Best practice:

- Store at 70°F / 50% RH

- Rotate stock

- Check manufacture date

- Wrong Tape Thickness or Construction

Why it fails

Too thin = no stress relief

Too thick = excessive creep if wrong adhesive

How the failure happens

Stress concentrates instead of being absorbed.

Examples

- Thin transfer tape on rough surfaces

- Foam tape used where rigid bond is required

Rule:

- Rough surfaces → thicker foam

- Rigid assemblies → thin transfer tape or film

- Unrealistic Expectations (Tape vs Fasteners)

Why it fails

Tape is used where mechanical fastening or structural bonding is required.

Examples

- Tape replacing screws in vibrating machinery

- Load-bearing brackets

- Safety-critical assemblies

Key point:

Tape is a bonding system, not magic.

Quick Failure Diagnostic Table

What You See | Likely Cause |

Clean release from surface | Poor prep / wrong adhesive |

Adhesive splits | Cohesive failure (overload) |

Edge lifting | Peel forces / moisture |

Slow sliding | Creep/ wrong adhesive |

Gummy residue | Chemical attack |