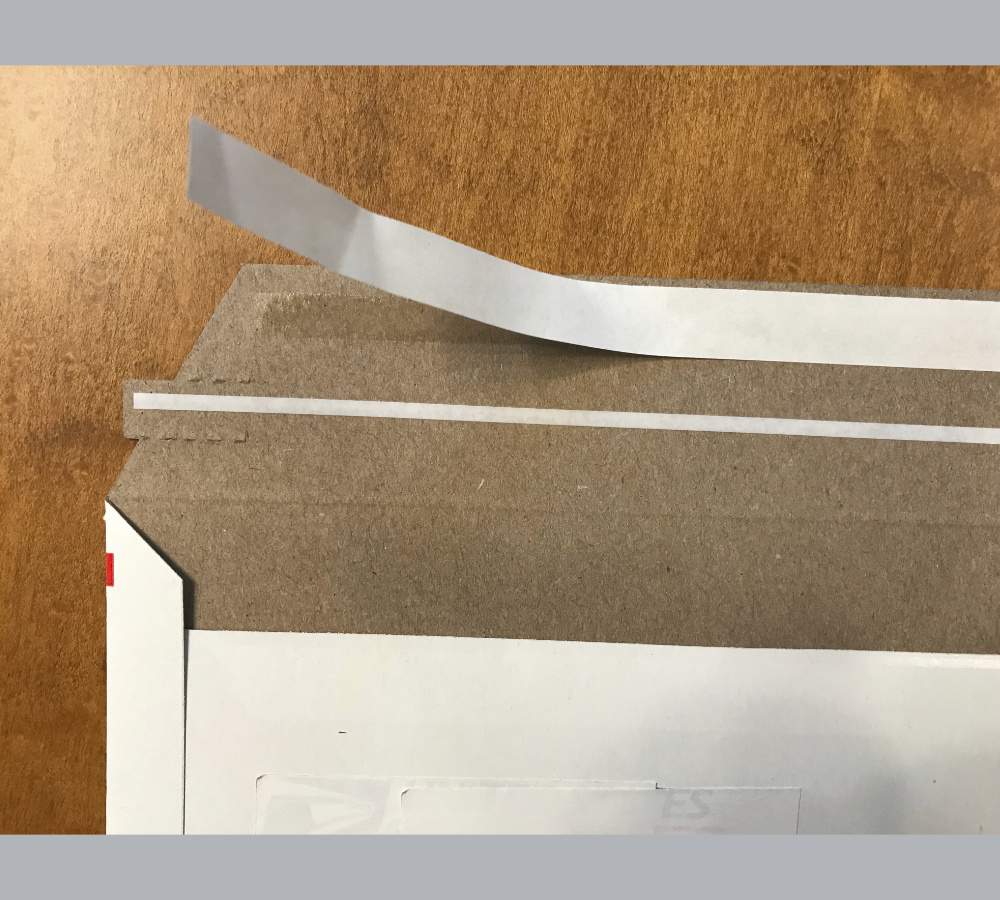

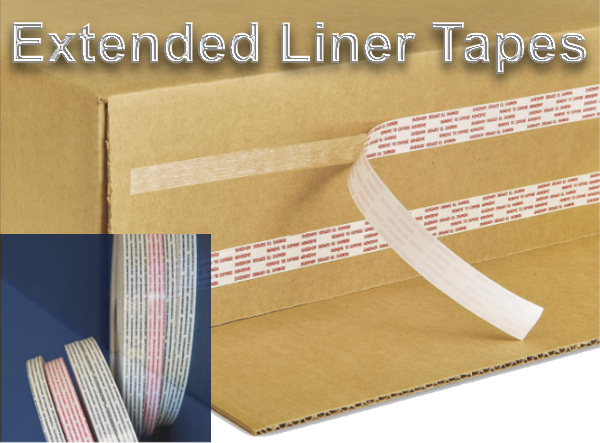

You have seen extended liner tapes on envelopes and boxes from USPS, FedEx, and UPS. They assist in removing the top protective adhesive liner; particularly when the liner is thin, it could be difficult to remove.

Customers sometimes ask for a heavier or thicker release lier to assist in removing the liner from the adhesive, however an extended liner may make more economic sense or improve effeciency.

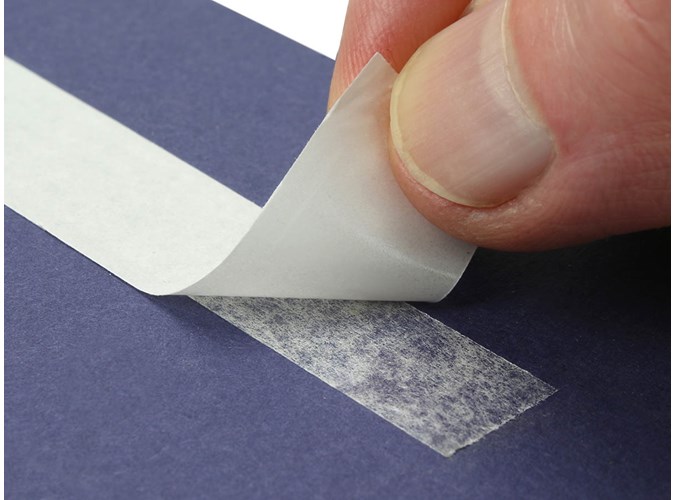

In the past, pressure sensitive tape manufactures, would use thick liners, but, in order to be more competitive in the market, converters started to introduce thinner weight liners to save costs. The problem was then that customers began to complain that the liner was difficult to remove. This has caused the growth in finger lift or extended liner tapes.

Not just used for e-commerce packaging, now they are used anywhere where you need to remove the liner quickly and hassle-free.

Manufactures could make the liner extended on both sides of the tape, one-side has extended liner while the other is flush, and even extended liner at the ends of the tape in the example below. These are mainly precut strips on a pad.

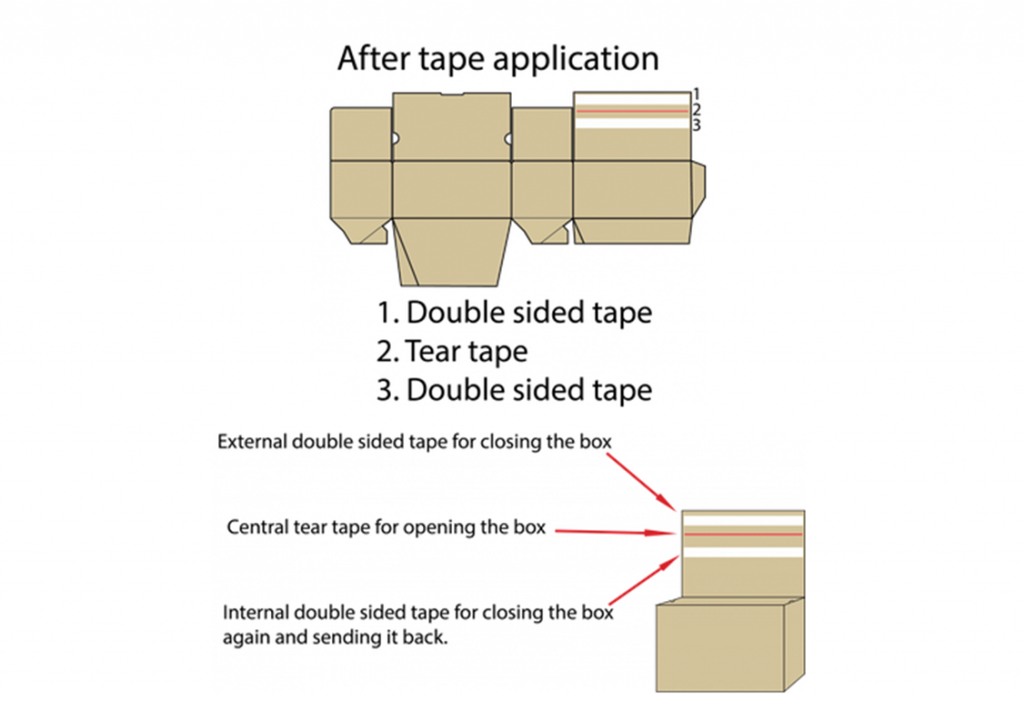

There are two types of finger lift tapes, the “traditional” finger lift style and the more recent “Dry Edge” or flood-coat zone-coat. This means that one side of the tape has full adhesive coverage while the “top side” of the tape has zone adhesive coverage or a dry edge.

The Dry edge allows you to have more coverage on one side while the other side had dry edges, allowing you to lift the tape. For manufacturing, the Dry Edge tapes are often more efficient (less cost per square inch of adhesive) to make than the traditional finger lift, which requires and extra step in the manufacturing process.In the sales sheet below, you see 1″ wide adhesive bottom adhesive layer and 3/4″ of adhesive on the top or liner layer.

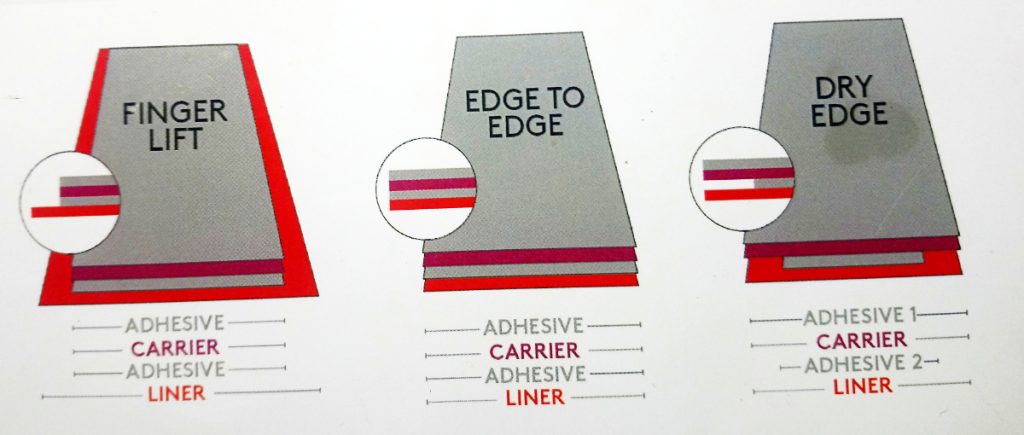

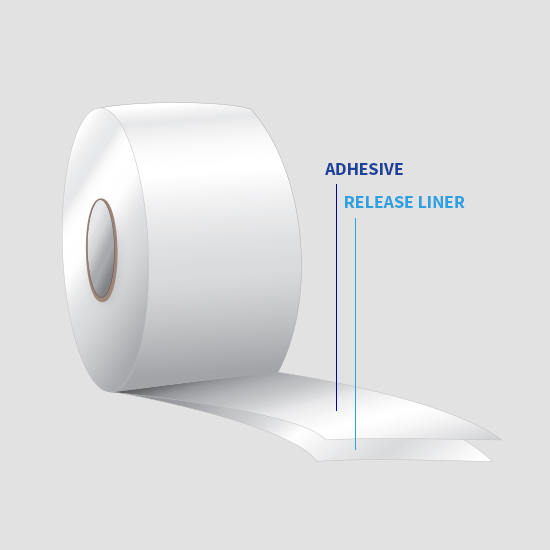

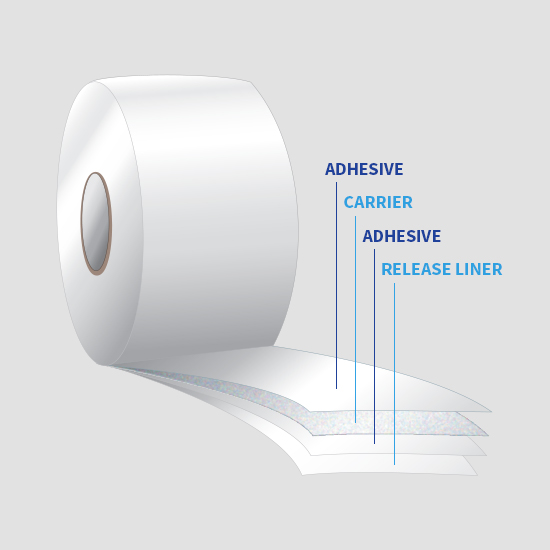

Like standard tapes, there are three most common constructions available.

- Transfer tape. These tapes, also known as unsupported tape, don’t have a center material, like a tissue or film in between the adhesive. It’s just pure adhesive, These are often used for envelope applications where a secure seal is needed but doesn’t not need to have the extra strength that you get from supported tapes.

- Tissue tape. This has a thin tissue carrier, the material in the middle of the adhesive. The tissue ads weight and thickness to the tape, making a stronger tape. The tissue adds flexibility for bending around curves or where the surface texture is rough. If you hold the exposed adhesive to light, you’ll be able to see the tissue in the adhesive.

- Film tape. This is a supported thin film, usually a polyester, that adds strong internal strength to the tape. You could usually tell if it’s supported with film because it will be much harder to tear by hand that tissue and transfer tapes.

- Foam tapes could also be produced with an extended liner, although not as common.

QuickStickTapes offers various extended liner constructions, length and width customizable. Contact for samples or price quote.