You might be inquiring of your tape supplier, because your customers are asking you, what adhesive tapes exist that you could use for e-commerce or transit packaging that are Eco-Friendly, Environmentally friendly, sustainable green and recyclable?

What makes an adhesive tape Eco-friendly or green?

We don’t know. Next question. But seriously, there is no industry standard as of now what defines an adhesive tape as “Eco-friendly” or “Green.” If used, these are marketing terms used to try to convey some kind of movement, operation, or materials used that will have a smaller carbon footprint. The adhesive tape industry could adopt some kind of industry-wide quantitative measurement that will help consumers choose between something that is less draining on our environment using a kind of scale. Perhaps something like the scale used to count the energy in food as calories. How much carbon calories does that roll of tape have compared to the same looking tape made by another manufacture? This will allow the consumer to make the intelligent choices when deciding among products.

What exactly is an environmentally friendly adhesive tape?

So the moment that factory worker switches on the lights in a plant to start the adhesive tape making process, the energy count to make the roll of tape begins. It’s impossible to make environmentally friendly tape, and the best we could hope for is an “environmentally friendlier” tape that is measured on a continuum

Then what adhesive tapes are friendlier, from most to worst?

There are certainly different ways to answer this question depending on your priority and concern for the planet’s health, which will change over decades and decades, centuries and centuries. But since reduction of greenhouse gases is our priority now, the environmentally friendlier tape is the one that has a smaller carbon footprint (greenhouse gas generated by an action).

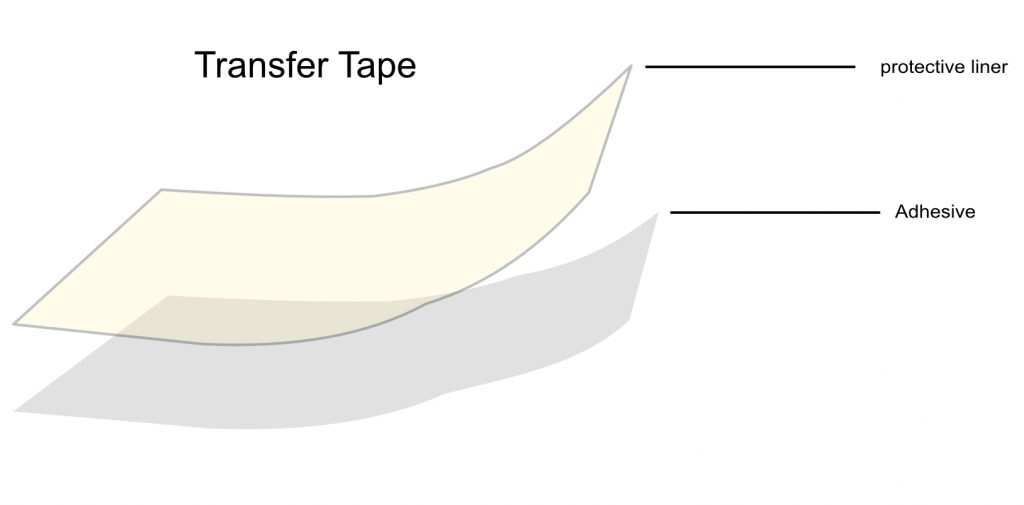

Transfer adhesive tape—will generally have less environmental impact because there is not an addition of material used in the middle of the adhesive (called a carrier that acts to strengthen the internal structure of the tape—like metal rebar acts to strengthen the cement in flooring). However, make a very thick transfer tape with high solvent content, it could not be so friendly. Note that people will call a transfer tape a double-sided tape because it’s sticky on both sides, but in industry technical terms, a true double-sided tape is categorized separately.

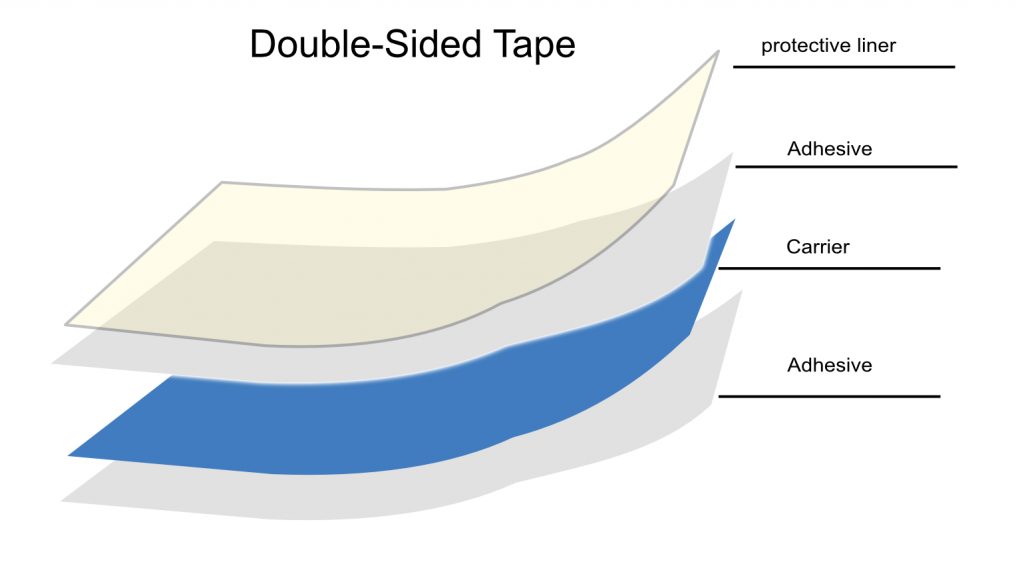

Double-sided tapes—these are made with different constructions. A double-sided tape is defined as a carrier having adhesive on both sides. Think of it like a sandwich, where the bread represents the adhesive layers and the middle layer could be any host of delicious things. The delicious thing in double-sided tapes that are commonly found is a non-woven tissue, paper, plastic film, and polyethylene foam. The polyethylene foam and the plastic film in itself contribute to a higher carbon footprint, then add to that a thick solvent based adhesive and you’re really on fire with that footprint.

What are my best options for a greener adhesive packaging tape and will it work?

There are smarter options for the consumer, and with improved technology even better options become available.

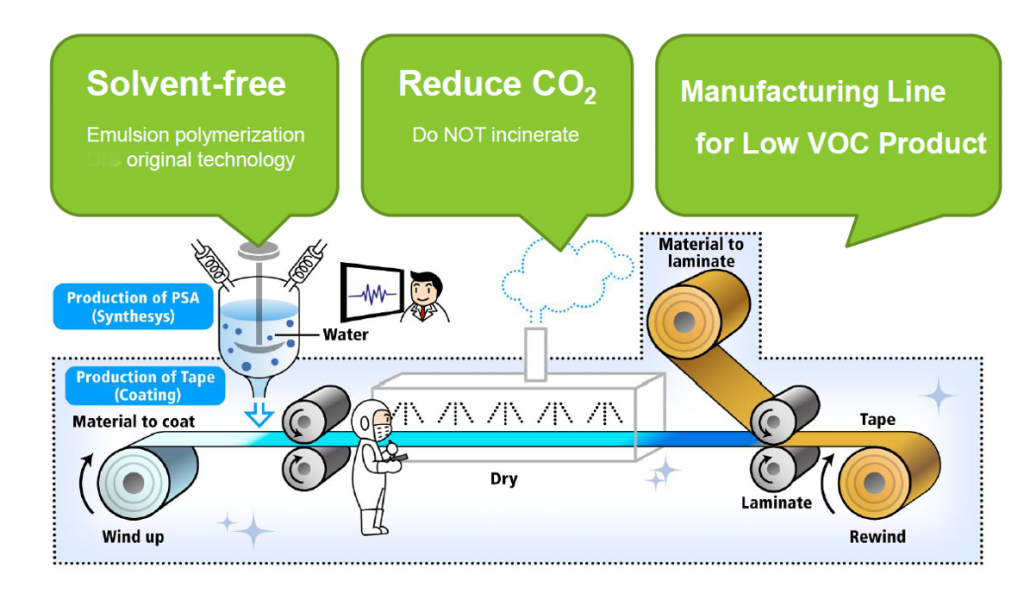

Use a water-based adhesive (less common) as opposed to solvent based adhesives where you can. Polymers dissolve in the solvent then the remaining solvent gets burned away in an oven, whereas water-based adhesives get their strength by compounds surrounded by water, then the water gets burned away in an oven.

Water based, or emulsion acrylic adhesives are getting stronger. In years past, they saw a very limited use because they could not produce the level of performance that a solvent based adhesive would, but now it’s possible to find water-based adhesive just as good as solvent based. Talk to your tape professional about your specific application to get advice.

Get it done with a transfer tape if you can. If you do need a carrier for your application, could your supplier use some post-consumer paper to give it internal strength? Does it really need to have a film carrier? We see it often where a tissue carrier could function just as well.

Often when you choose an alternative to a carbon rich product, you sacrifice price and pay more to behave friendlier to the plant. The good news with water-based adhesives, you could often pay less for a similar performance. Talk to your supplier about your options.